產品中心 分類

≡ 欄目: 擺線減速機 ≡ 發布時間: 2023-03-25 ≡ 點擊數: 971

一、前言FOREWORD

行星擺線針輪減速機,是一種應用行星傳動原理,采用擺線針齒嚙合,設計先進,結構新穎的減速機構。該減速機可以廣泛應用于各種傳動機械中的減速機構,如:起重、運輸、礦山、治金、石化、紡織、印染、輕工、制藥、糧食、飼料、食品機械等等。

Planet cycloidal pin gear reducer is a speed reducing construction with advance design, novel structure adopting theprinciple of planet driving and the falling-in of cycloidal pin gear, This reducer can be widely applied to the speedreducincstructure of various driving machineries, such as; lift, transportation, mine, metallurgy, petrolchemical, texitle, prention,lighiindustry, pharmacy, food, forage, food machinery, tec.

Planet cycloidal pin gear reducer is a speed reducing construction with advance design, novel structure adopting theprinciple of planet driving and the falling-in of cycloidal pin gear, This reducer can be widely applied to the speedreducincstructure of various driving machineries, such as; lift, transportation, mine, metallurgy, petrolchemical, texitle, prention,lighiindustry, pharmacy, food, forage, food machinery, tec.

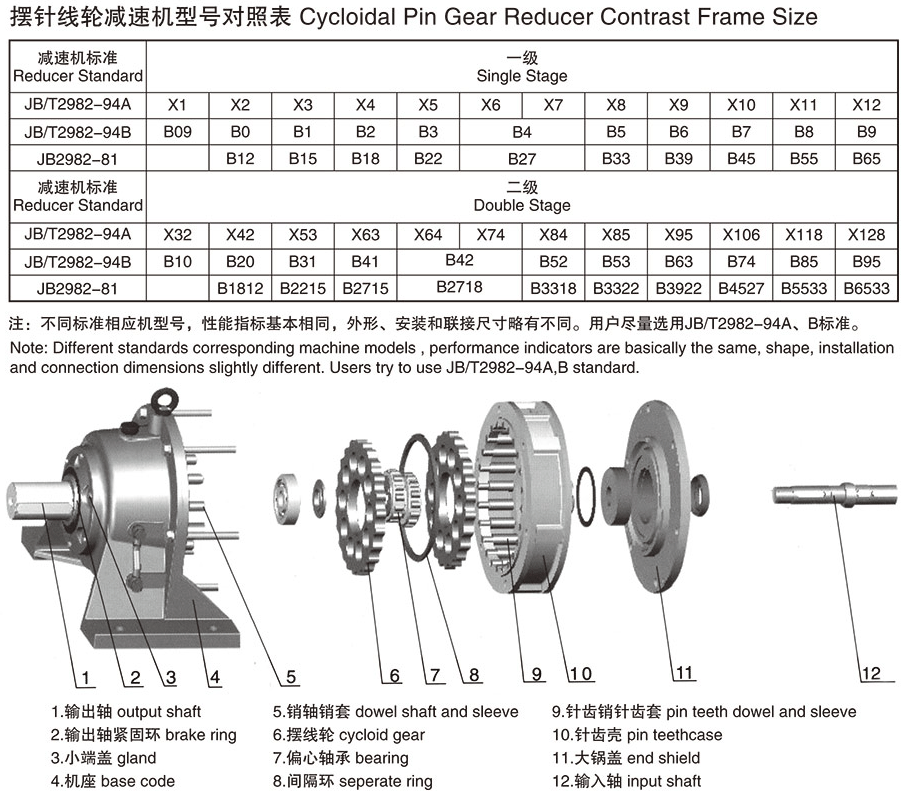

二、傳動原理與結構DRIVING PRINCIPLE & CONSTRUCTION

行星擺線針輪減速機的傳動原理如圖1如示:

輸入軸1和轉臂3一起繞中心Ob順時針方向回轉時,擺線輪2即隨轉臂一道繞中心Ob公轉。由于固定在針齒殼5上的針齒的反作用使擺線輪繞其本身中心OC逆時針方向自轉,并通過銷套銷軸將其自轉等速傳遞給輸出軸4,故輸出軸就得到了與輸入軸相反轉向的運動(輸入軸轉動一周,輸出軸擺線輪轉動-I/EC周),其減速比為:

The Driving Principle of Planet cycloidal pin gear reducer is showed in the diagram 1.When input shaft 1 and rotating arm 3 are rotating around the OB Axis in chocdwise the cycloidal gear 2 will rotate aroundthe Sxis OB togethert the rotating arm. The cycloidal gear wll self-rotating around OC in countclockwise due to the counteractiorof pin gear fixing in the pin gear shell 5, meanwhile, the self-rotation speed will be passed to output shaf 4 through pin shaft.as result, the output obtain the contrary movement against input shat. (When input shaf rotate one cycle, the output cycloidalgrat will rotate -1/EC cycle.), its velocity-reducing ratio is:

i=(Ec-Eb)/Ec=-I/Ec 其中:EC-Eb)=-1

i=(Ec-Eb)/Ec=-I/Ec among it:Ec-Eb=-1

Ec--擺線輪齒數 Eb--針齒齒數

The Driving Principle of Planet cycloidal pin gear reducer is showed in the diagram 1.When input shaft 1 and rotating arm 3 are rotating around the OB Axis in chocdwise the cycloidal gear 2 will rotate aroundthe Sxis OB togethert the rotating arm. The cycloidal gear wll self-rotating around OC in countclockwise due to the counteractiorof pin gear fixing in the pin gear shell 5, meanwhile, the self-rotation speed will be passed to output shaf 4 through pin shaft.as result, the output obtain the contrary movement against input shat. (When input shaf rotate one cycle, the output cycloidalgrat will rotate -1/EC cycle.), its velocity-reducing ratio is:

i=(Ec-Eb)/Ec=-I/Ec 其中:EC-Eb)=-1

i=(Ec-Eb)/Ec=-I/Ec among it:Ec-Eb=-1

Ec--擺線輪齒數 Eb--針齒齒數

Ec - Tooth No.If cycloidal gear, Eb-pin gear No

由上式可知當輸入軸轉Ec轉時輸出軸則反向轉1轉

According to above formula, shen input shaft rotate Ec cycles, the output shaft wil rotate one cycle in counterdirection.

According to above formula, shen input shaft rotate Ec cycles, the output shaft wil rotate one cycle in counterdirection.

行星擺線針輪減速機全部傳動裝置可分為三部分:輸入部分;減速部分;輸出部分

The entire Driving Assembly can be divided into three parts; input part; speed-reducing part; output part.

The entire Driving Assembly can be divided into three parts; input part; speed-reducing part; output part.

三、特點CHARACTERISTICS

1、減速比大;一級減速時速比為1/11 - 1/87;二級減速時速比為1/121 -1/5133;三級減速時速比為1/2057-1/446571;根據需要可以采用更多級組合。

2、傳動效率高:由于該機嚙合部位采用了滾動嚙合,故效率可達90%以上。

3、體積小,重量輕:由于不僅采用了行星傳動原理,輸入軸和輸出軸在同一軸線上,而且有與電動機直聯呈一體的獨特之處,因而本機具有結構緊湊,體積小,重量輕的特點。

3、體積小,重量輕:由于不僅采用了行星傳動原理,輸入軸和輸出軸在同一軸線上,而且有與電動機直聯呈一體的獨特之處,因而本機具有結構緊湊,體積小,重量輕的特點。

4、故障少,壽命長:本機主要轉動嚙合件采用軸承鋼制造,因此機械性能好,耐磨性好,再加采用滾動摩擦,故使之

故障少,壽命長。

5、運轉可靠平穩,本機傳動過程中為多齒嚙合,所以使之運轉平穩可靠,噪聲小。

6、拆裝方便,容易維修:由于結構設計合理拆裝簡單便于維修。

7、本機還具有過載能力強,耐沖擊、慣性力矩小、適用于起動頻繁和正反轉的特點。

3. Small volume, light weight: this machine has compacted structure,small volume and light weight because of adoptingthe priciple of planef driving so that the input shaft and output shaft in the same axis,moreover,they will integrated witrthe motor.

1.Big Volecity-Reducing Ratio: for single-stage speed-reducing, the ratio is 1/11-1/87; double-stage speed-reducingthe ratio is 1/121 - 1/5133: three-stage speed reducing, the ratio is 1/2057 - 1/446571; we can adopt more-stages compouncaccording the requirement.

2.High Driving efficiency: the driving effciency can reach above 90% due to adopting rolling engagement in falling-in part3. Small volume, light weight: this machine has compacted structure,small volume and light weight because of adoptingthe priciple of planef driving so that the input shaft and output shaft in the same axis,moreover,they will integrated witrthe motor.

4, Few troubles,long life: this machine has good resistance to abrasion because the main driving engaging parts

are made of bearing steel and applying rolling friction.

5. Stable Running: For most driving procedure, we adopt multi-teeth falling-in. so the running will be stable and

little noise.

6. Convenient dismounting, easy maintanance: Due to reasonable structure and design.

7. This machine also are of the characteristics such as strong overloading ability, ability,anti-compact, Samll inertiamoment, which are suitable for frequently start and double-side rotation.

7. This machine also are of the characteristics such as strong overloading ability, ability,anti-compact, Samll inertiamoment, which are suitable for frequently start and double-side rotation.

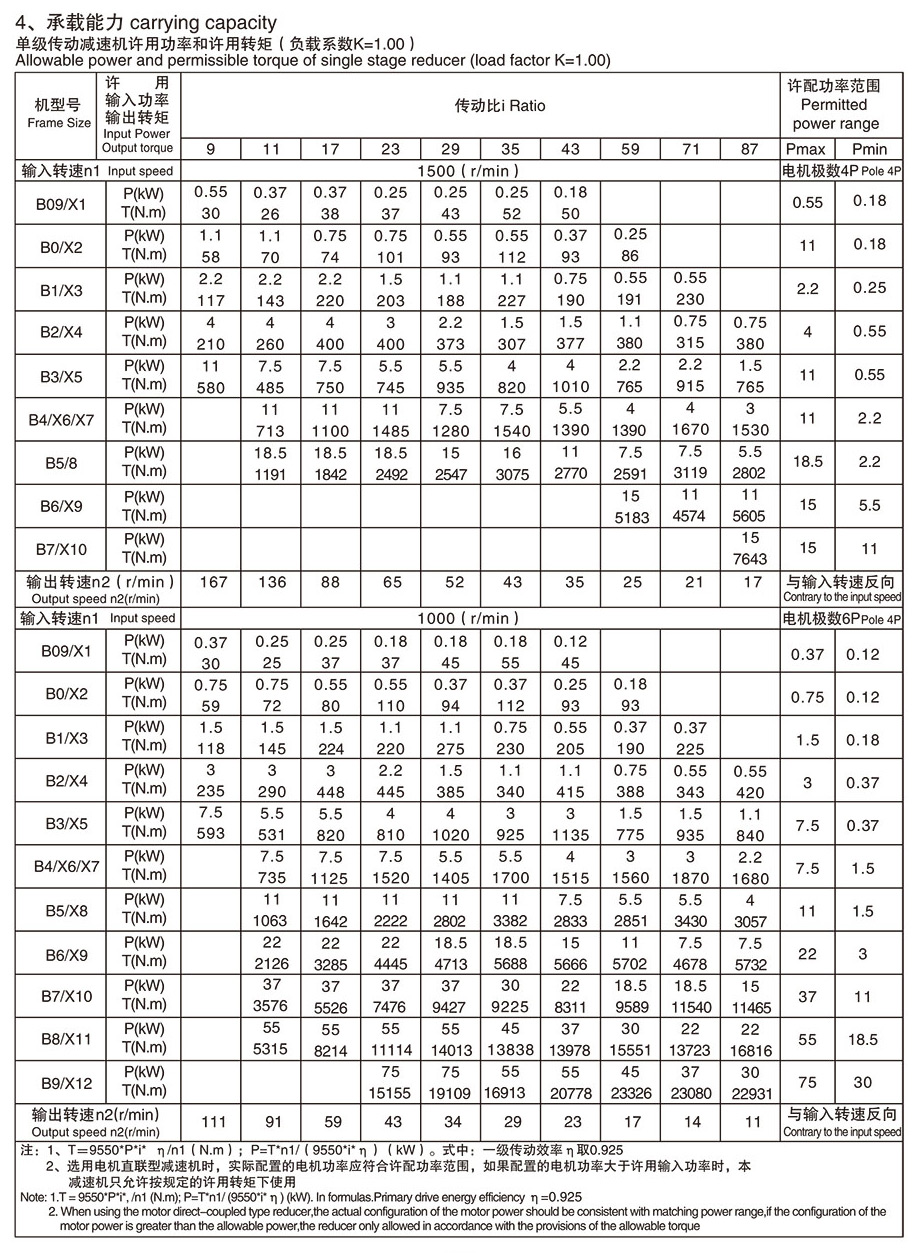

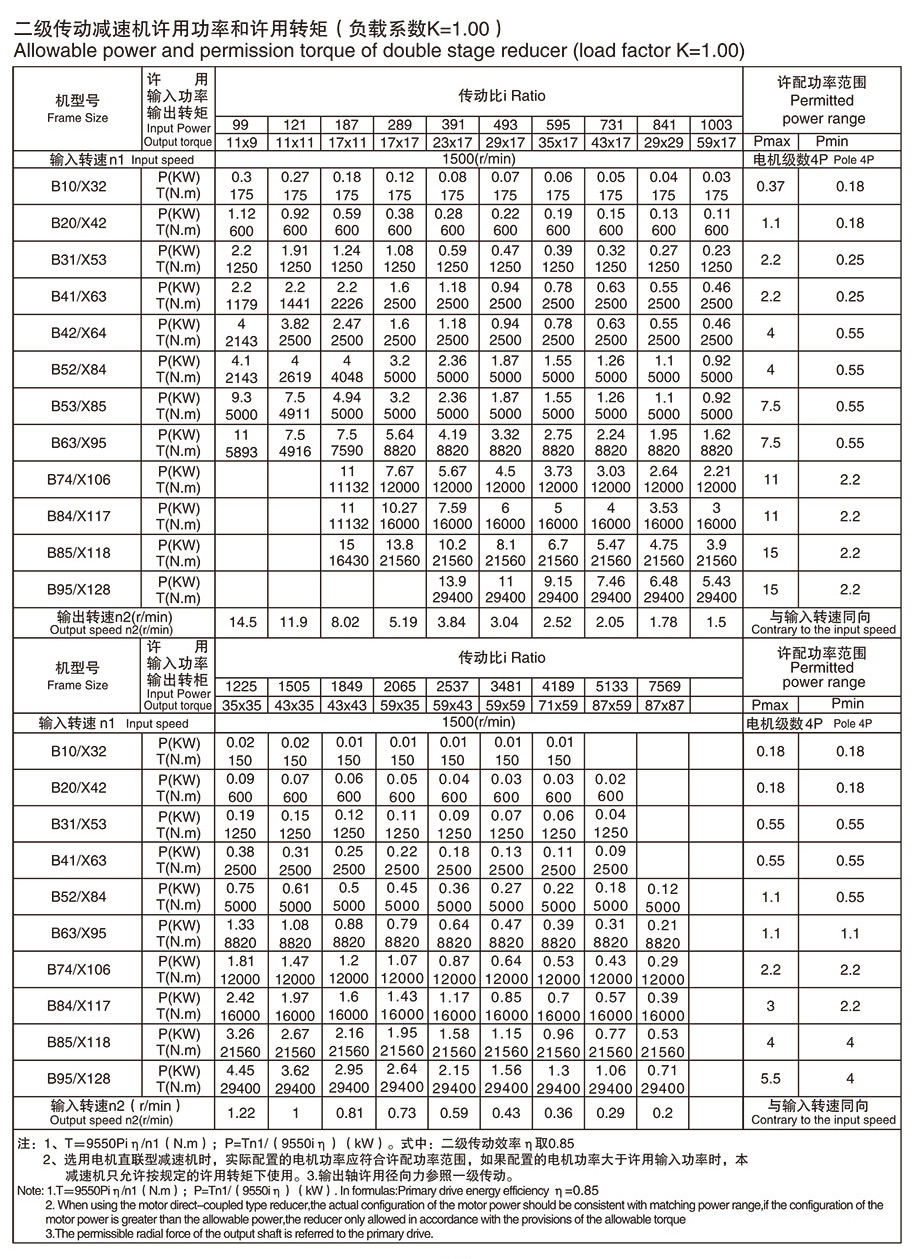

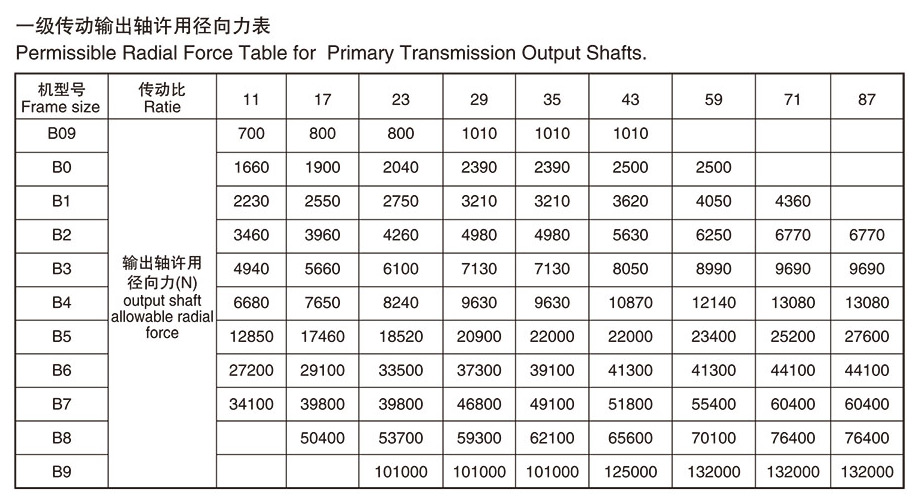

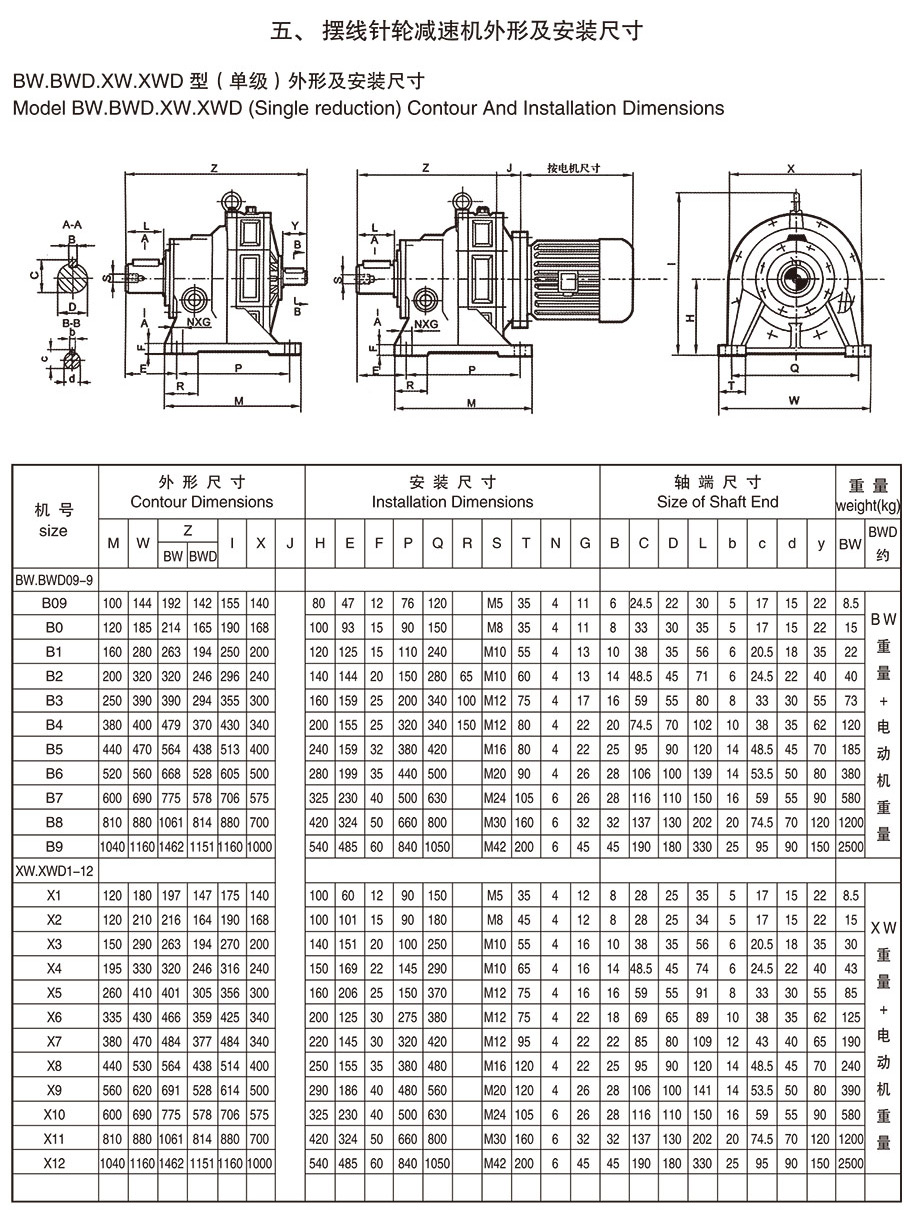

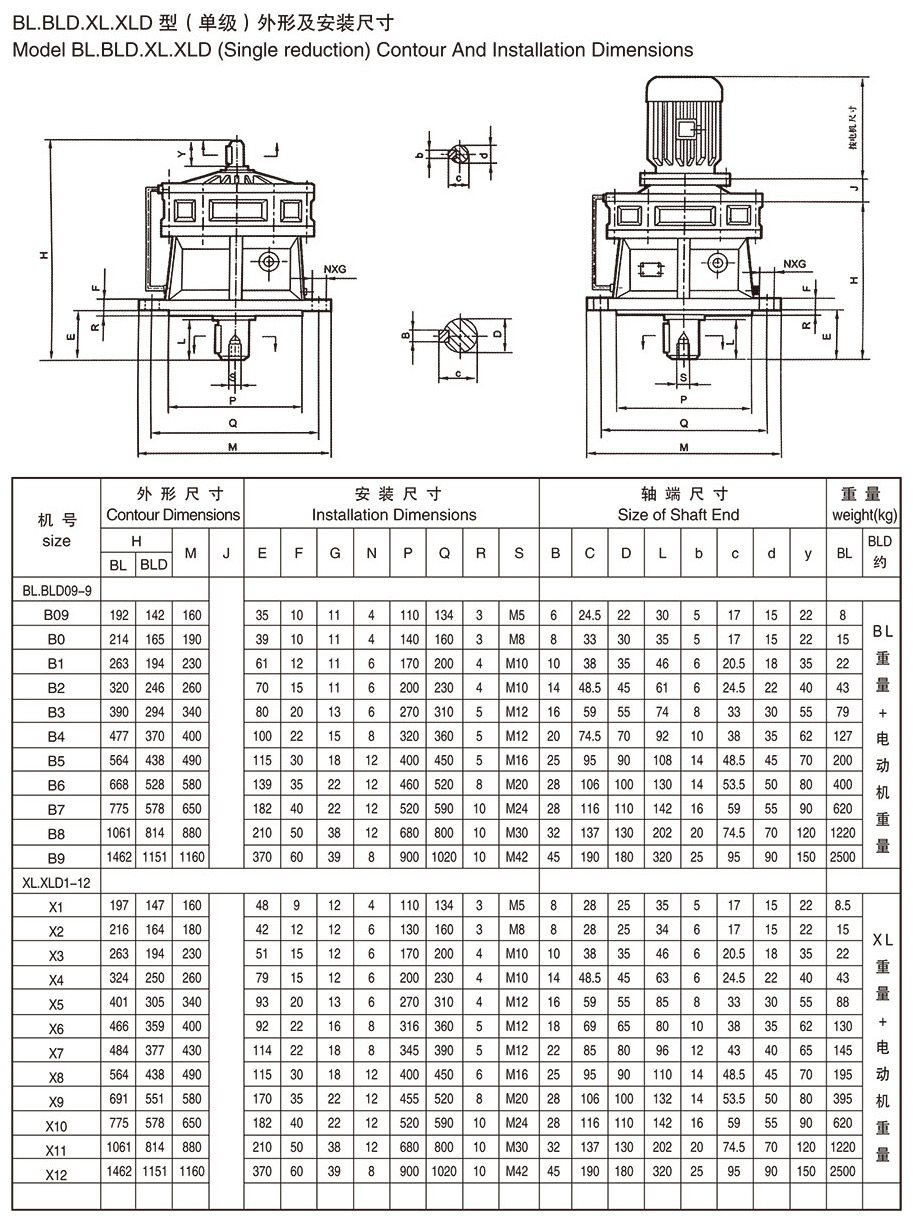

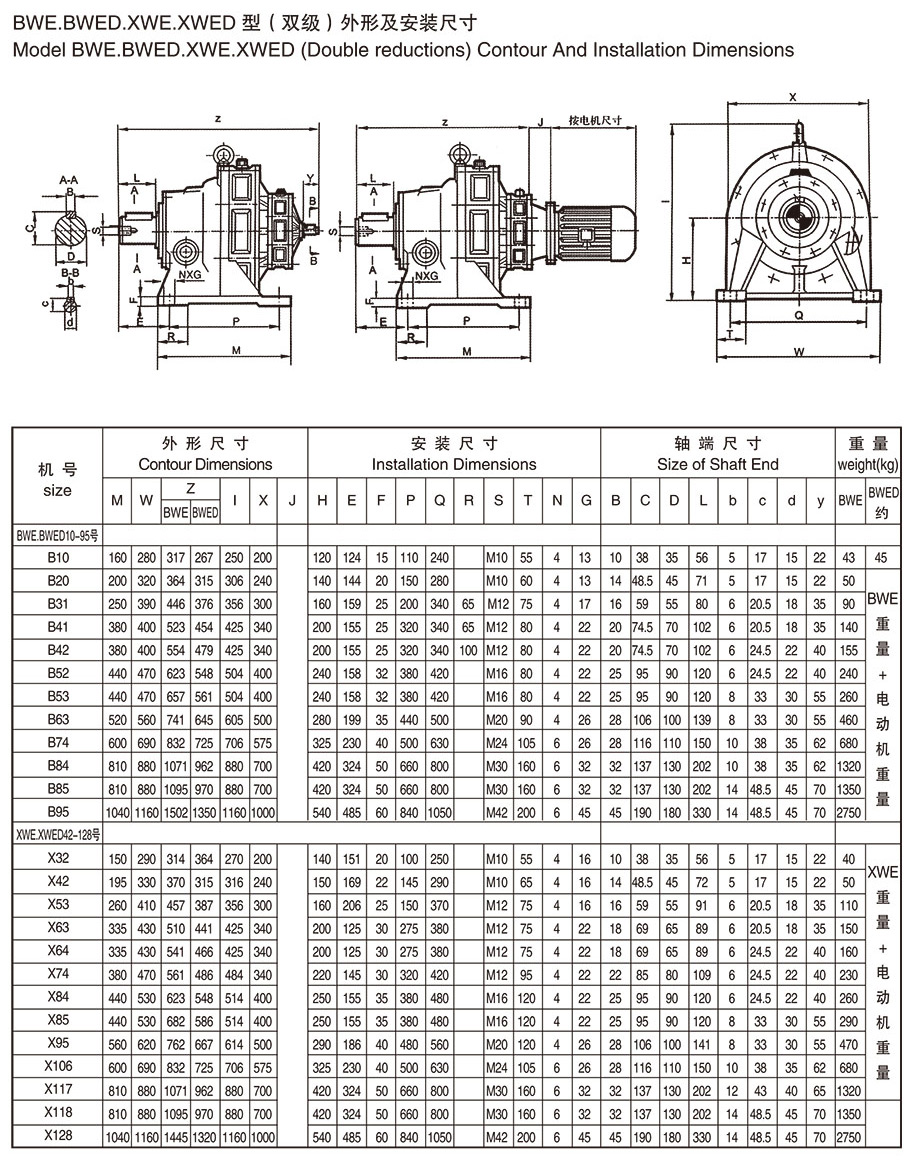

四、技術規格TECHNICAL DATA

- 上一個:

- 下一個:

官方微信關閉